Timing Belts & Chains

We have a wide range of Timing belts & Timing Chain Kits. We stock Dayco belts & Ultra OEM chain kits. Please call 01708 890494 for more details.

Enquire NowTiming Belts & Kits

The timing belts keep the engine in sync. After time, the belt and its components need to be replaced. Please check your service schedule to see when your replacement is due. The belt, rollers & tensioners should be checked periodically to ensure there is no damage or wear to the belt and that the rollers spin freely. If the cam belt fails the engine will have a catastrophic failure often resulting in bent or broken valves, snapped camshafts and damaged piston crowns. This is typical in an interference engine, which means the valve protrudes into the space where the piston reaches.

Trouble Chart - Timing belt automatic tensioner (Source: Dayco)

Metal contamination and oxidation

Causes: Contact with contaminating components: oil, dust, leakage of coolant

Actions: remove leakage of coolant

Remove leakage of oil and/or fuel

replace the faulty/damaged component

Broken central pin

Causes: Incorrect setting of the bolt: the torque applied is higher than the value specified on the maintenance sheet.

Actions: apply the correct tightening torque

use the torque wrench

replace the faulty/damaged component

Broken Stop Contact

Causes: Incorrect setting of the tensioner: "excessive unload" condition with the belt excessively slack in the transmission

Incorrect setting of the tensioner: "excessive load" condition with the belt is tensioned in the transmission.

Actions: replace the components when the engine is cold

Apply the correct tension to the belt

Check the alignment of the reference indexes

Check the belt tension after the adjustment turns

Use the tensiometer to check the belt tension

replace the faulty/damaged component

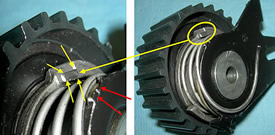

Broken stop contact / Dents on the end stop

Causes: Incorrect setting of the tensioner with loss of capacity to modulate and compensate the belt tension variations

Actions: replace the components when the engine is cold

Apply the correct tension to the belt

Check the alignment of the tensioner reference indexes

Check the belt tension after the adjustment turns

replace the faulty/damaged component

Timing Chain Kits

Chains generally have a longer service life than belts, but chains and their components must be checked regularly. Servicing is critical to the operation of the chain. Often, the chain tensioner works under oil pressure. If the oil is low or insufficient oil reaches the tensioner, the chain will run without enough tension which can damage guide rails and sprockets.