Camshafts & Followers

Here at Engine Parts (UK) LTD we stock a massive range of hydraulic tappets & lifters, cam buckets, cam followers, rocker arms & camshafts at our main distribution hub in Essex. We keep OEM parts as well as aftermarket products from AE, Freccia & Ajusa. We can source INA, Febi Bilstein, Estas, Kent Cams and other brands as a special request.

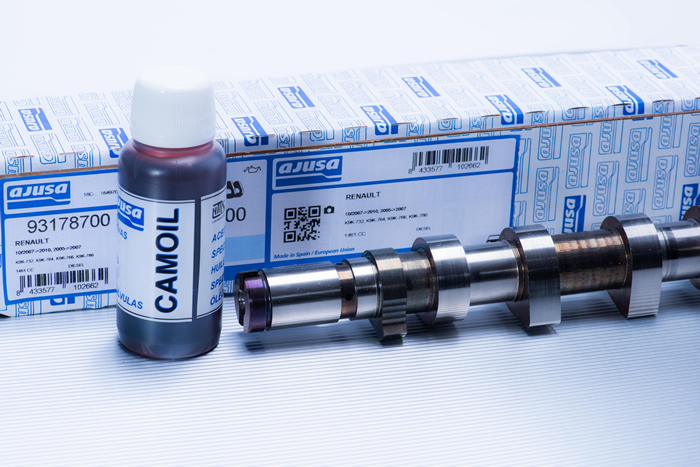

Camshafts

Camshafts are used to set the timing of the valve train. The lobes on the camshaft determine how much a valve protrudes and its duration. We can source performance camshafts where the valve lift or timing needs to be changed to increase power / torque at a given engine speed. Camshafts are made in different materials and different methods are used to construct the camshaft. Many are chilled cast iron construction which is cast and then precisely machined to specification. Other camshafts are constructed in a manner where the cam lobes are "sweated" onto a shaft. If your engine has this type of camshaft and suffers a timing failure, the lobes can be moved on the shaft without notice. This can cause mechanical failure if the camshaft is fitted with the lobes in the incorrect position. The camshaft should be checked by a local engine remanufacturer to ensure they are "in time". Some engines require a billet steel camshaft where the whole shaft is machined from hardened steel.

Rocker Arms

Rocker arms transfer mechanical energy from the camshaft to the valve. The camshaft may be in direct contact with the camshaft or by a push rod. Push rods are typical in engines which have an OHV (overhead valve) design.

Hydraulic Lifters

Hydraulic lifters rely on engine oil & pressure to ensure the correct valve clearance. Sticking hydraulic tappets / lifters can be audible through the valve train and cause premature engine wear. Regular servicing and using the correct oil are critical for smooth hydraulic action.

Cam Buckets

Cam buckets are mechanical lifters that are often in direct contact with the camshaft. These buckets are cylindrical and have a range of different lengths or a recess for a tappet shim. The bucket length will determine the valve clearance. You should calculate which shim thickness or bucket length you will need to achieve this.

Trouble Tracer Chart

(source: Federal-Mogul)

Carbonised oil deposits

Appearance: Carbonised oil build-up on cam and followers.

Causes: Excessive operating temperatures resulting from marginal lubrication conditions due to contaminated lubricating oil or blockages/restrictions in oil feed galleries.

Remedy: Thoroughly flush the lubrication system, ensuring that all galleries and hydraulic tappets / lifters (where fitted) are free from blockages & debris. Install new camshaft and followers, prime with extreme pressure lubricant and replace oil and filter.

Base circle contact marking

Appearance: Witness marking on the base circle of cam-lobes, biased to one side.

Causes: Worn lifters and/or retainer springs.

Remedy: Replace cam and followers if marks are deep, otherwise set tappets to correct clearance. Thoroughly flush the lubricating system and replace the oil and filter.

Cam-lobe and follower wear

Appearance: Premature wear of one or more cam-lobes & followers. The follower contact surface will be concaved with chipped edges.

Causes: Incompatible cam-lobe & follower contact surface geometry. Often caused by fitting new camshaft with old followers or vice versa. This can also result from lubricant starvation from a blocked or restriction in oil supply.

Remedy: Thoroughly flush the lubricating system, replace the cam and followers, prime with extreme pressure lubricant and replace oil and filter. Do not mix old and new components.

Follower breakage

Causes: Mechanical overload resulting from:

1 Sticking or seized valve, resulting in the follower breaking due to cam-lobe pressure.

2 Piston contact with the valve due to:

- Weak valve spring

- Over extended lifter or tappet

- Incorrect assembly of valve tip-cap

- Timing belt breakage

- Or through over-high revving of the engine.

3 Incorrect valve timing.

Remedy: investigate & rectify the mechanical overload cause. Thoroughly flush the lubricating system, replace all damaged components, prime cam and followers, with extreme pressure lubricant and replace oil and filter.

Excessive cam-lobe wear

Appearance: Severe cam-lobe wear.

Causes: Contaminated lubricating oil, tappet clearances too tight, excessive valve spring pressure.

Remedy: Thoroughly flush the lubrication system, and install new camshaft and followers. Adjust tappets to the correct clearances, prime with extreme pressure lubricant and replace oil and filter

Broken camshaft

Appearance: Camshaft breakage between or through cam-lobes.

Causes: Severe distorted camshaft housing or cylinder head. Incorrect torque sequence and mishandling can also cause similar breakage.

Remedy: Straighten or replace the camshaft carrier/cylinder head, use the correct bolt torque sequence and handle with care. Thoroughly flush the lubricating system, replace the cam and followers, prime with extreme pressure lubricant and replace the oil and filter.

‘Scored’ bearings

Appearance: Severe scoring of the camshaft bearings.

Cause: Contaminated lubricating oil, i.e. foreign particles circulating in oil.

Remedy: Thoroughly flush the lubricating system & replace the cam and followers, prime with extreme pressure lubricant and replace oil and filter.

Overheated camshaft

Appearance: Cam-lobes, bearings & followers have a ‘blue’ discoloration.

Causes: Severe overheating of the engine due to malfunction of the cooling system.

Remedy: Investigate and rectify the cause of the overheating. Thoroughly flush the lubricating system, replace cam and followers, prime with extreme pressure lubricant and replace oil and filter

Physical damage to camshaft & followers

Appearance: Cam-lobes, bearings & followers “chipped”

Causes: Excessive end-float due to:

a). Worn thrust washer

b). Loose distributor

c). Worn distributor drive gear

d). Or misaligned timing gears

Remedy: Investigate and rectify the cause of the damage. Thoroughly flush the lubricating system, replace the cam and followers, prime with extreme pressure lubricant and replace the oil and filter.