ACL Technical Bulletin

ACL - Bearings without Locating Notches.

There are a number of bearing sets for late model engine applications which contain bearings with no locating notch (lug).

This design is usually specified by the OEM engine manufacturer, and is in line with the current OEM design practice of eliminating this feature on bearings.

Most of the major OEM Manufacturers have specified this design on some of their engines. This ‘notchless’ design can be used in place of the previous notched bearings, where there has been a change to the new design, later in an engine series.

For OEMs that have the luxury of automated engine assembly, the notch has become a redundant feature. However, when assembling an engine featuring notchless bearings by hand, greater attention needs to be paid to bearing alignment and orientation.

Without the aid of notches, the engine rebuilder needs to ensure that bearings are:

1. Located centrally in their housing

2. Located with upper and lower shells in the correct orientation

3. Bearing pairs are aligned

4. Grooves and oil holes are in line with oil feed galleries.

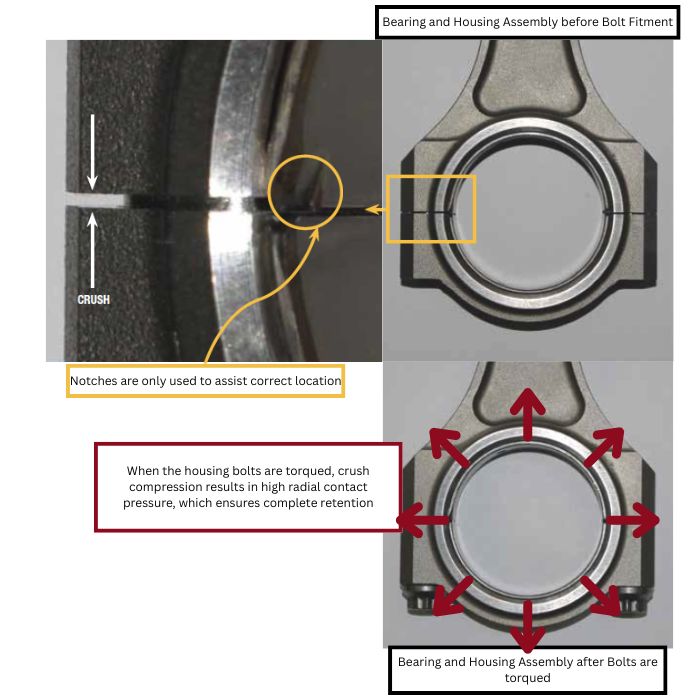

Bearing Retention

When confronted with notchless bearings, some engine builders have expressed a concern that, without the notch, a bearing pair has greater freedom to move or ‘spin’ during use.

This is not the case as a notch is a fitment/location guide only and does not assist bearing retention.

It is the bearing crush which ensures that the bearings are held tightly in the housing. Once the bolts are torqued, this sets up radial pressure in the housing, binding the bearings in place.